Established in 2011, Olsheng is a professional lead-free electronic equipment manufacturer integrating R&D, production and sales. The company has lead-free reflow soldering, lead-free wave soldering, domestic chip mounter, solder paste printing machine, board loading and unloading machine, PVC production line, SMT peripheral equipment and THT complete line equipment of the full set of production capacity, can provide customers with the right price, excellent quality lead-free electronic equipment products.

Establishment

Factory area

employees

equipment

Annual production

Using world-leading microcirculation technology, the entire furnace is divided into 2,800 individual cells. Compared with the small circulation structure, the hot air of the small circulation structure will be recycled by the return air outlet around the furnace after blowing out of a furnace distance, and in the recovery process, it will constantly interfere with the gas blown out of other outlets in the furnace, resulting in continuous fluctuations in the temperature curve on each PCB, so that its welding accuracy is affected.

Wave soldering is a commonly used surface mount soldering process for bulk soldering of large quantities of electronic components onto printed circuit boards (PCBs). In wave soldering, components on a circuit board are moved by a conveyor belt to a preheating zone, and then passed through a solder surge zone (wave crest) to be immersed in molten solder to be soldered.

Use the most convenient positioning block, substrate origin alignment method of positioning, positioning accuracy (accuracy less than 0.05mm). Mounting angle range 0-360 °, precision 0.1 °. Each suction nozzle is independent of the corner, plus six components identification camera, in addition to mounting the traditional LED long light bar, bulbs, downlights, spotlights, ceiling lamps, guardrail tube, LED driver power supply, control boards, etc. can be mounted at will.

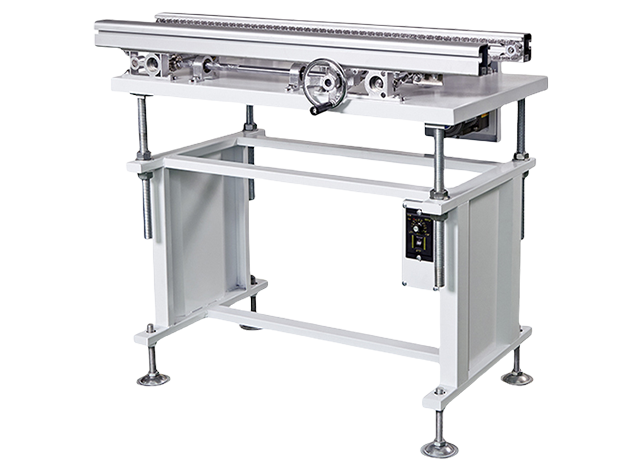

Used for the front end of the wave machine and the production line to connect the use; the use of nylon chain transport, the product will not slip; when the wave soldering welding angle adjustment, only need to adjust into the board to connect without moving the plug-in line. The speed of transport belt is adjustable, stable and reliable work. Four-legged bracket is more stable.

Computer control, stable and reliable work; LCD screen display, menu operation interface, man-machine dialogue is convenient; a number of sound and light alarm function; standard material box can be used, versatility; according to the PCB thickness can be set up to lift the frame step; under the machine built-in push plate mechanism, eliminating the need to buy a separate push plate machine; with automatic counting function, to facilitate the production of statistics; equipped with a signal communication structure, can be connected with other machines online.

Customised Fast

Customised Fast high energy efficiency

high energy efficiency high efficiency

high efficiency high stability

high stability intelligent

intelligent high precision

high precision

Oxidation during reflow is a common problem that can cause loose or broken conne...

View Details >>Wave soldering, also known as solder melting, is a soldering method performed on...

View Details >>Reflow soldering is an important process in the SMT production process. It mainl...

View Details >>When using a wave soldering station to remove the board from the board, you need...

View Details >>Building 2, No. 90, Saierkang Avenue, Furong Industrial Zone, Xinqiao Street, Bao'an District, Shenzhen, China.

13632723882

e.ols-smt.com

0755-27299229

onlysmt007@163.com

Copyright © Shenzhen Olsheng Technology Co., LTD. All rights reserved[ 粤ICP备2024272522号]Site Map|RSS